Against the backdrop of the boom in electric heavy trucks and the rollout of 3C mandatory certification, EAST Group – drawing on 36 years of power electronics expertise and experience from operating 50,000 global charging stations – presents its answer with the “Heavy Truck + Ultra Charging + V2G” all-scenario solution.

Recently, the China Quality Certification Center hosted a conference on “Leading the New Journey · Quality Shaping the Future” in Shenzhen, focusing on quality upgrading and innovative development of charging infrastructure.

Chen Mingxiang, Director of R&D for EAST Group’s charger products, was invited to attend and deliver a speech, sharing insights on quality upgrading of charging infrastructure, technological innovation practices and reflections.

Industry Fervor: Quality Enhancement Emerges as Critical

During his speech, Director Chen Mingxiang noted two key “growth drivers” in the new energy sector: First, electric heavy-duty truck sales have boomed, surpassing 82,000 units in 2024—a 139.4% year-on-year increase—while dedicated commercial vehicle charging piles remain under 20,000, satisfying only 40% of demand. Second, policy upgrades: mandatory 3C certification for charging piles takes effect in March 2025, shifting the industry focus from “quantity” to “quality.”

This aligns closely with the conference’s core theme. Zheng Shiquan, Assistant General Manager of the China Quality Certification Center, stressed in his address that charging infrastructure is critical to high-quality growth in new energy vehicles. Its quality and reliability directly impact the execution of national new energy strategies and public safety. EAST Group consistently prioritizes product innovation and operational upgrades, leveraging robust technical and service capabilities to empower the industry and drive high-quality development of charging infrastructure.

Product Innovation: Full-Scenario Solution

In response to the unique operating conditions of electric heavy trucks—such as high altitudes and heavy dust in mining zones, severe salt spray in ports, and the “charge-and-go” requirement on highways—EAST Group offers three tailored solutions:

- For enclosed mining areas: 320-480kW dual-gun all-in-one units, designed to operate reliably in temperatures from -40℃ to 60℃ and at 3,700-meter altitudes. Featuring IP55 protection and 40PPI dust screens, they boast a failure rate below 2%.

- For ports/logistics hubs: 360-480kW integrated systems with 15-day rapid deployment. Dual-gun concurrent charging boosts efficiency by 50%.

- For highway arteries: 720-1440kW split charging piles combined with 1200A liquid-cooled terminals. A 300kWh battery reaches 90% charge in 15 minutes, delivering over 300km range—80% more efficient than conventional chargers.

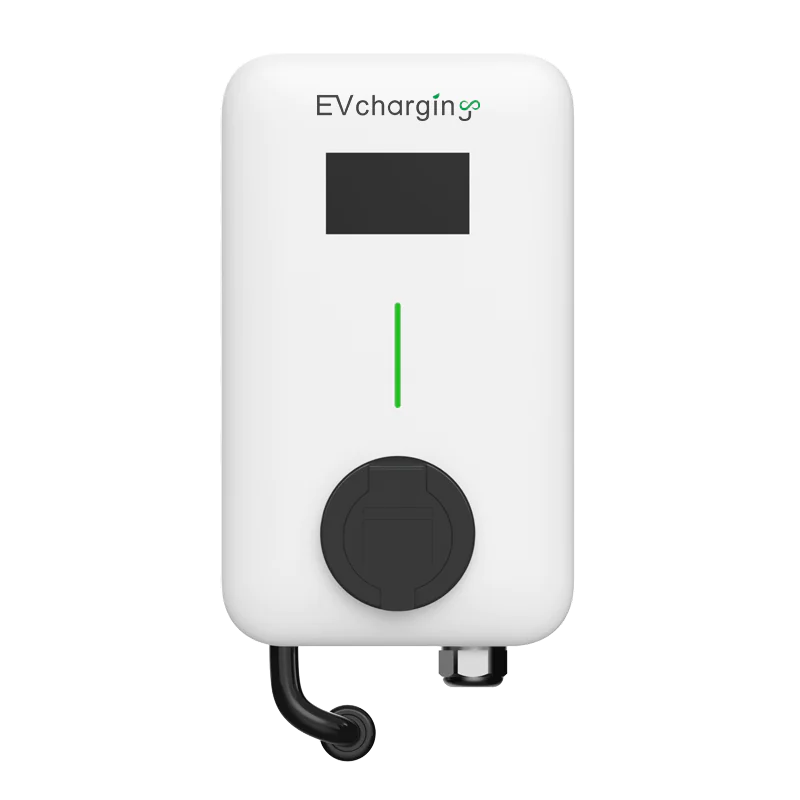

EAST Group’s newly released 360-800kW full liquid-cooled ultra-fast chargers boast four “ultimate” strengths:

- Ultimate speed: 1000A per gun, 2000A with dual guns, over 96% efficiency; 800kW single cabinet scalable to megawatt capacity.

- Ultimate quietness: 55dB supercritical silent performance, ideal for noise-sensitive environments like premium neighborhoods and business hubs.

- Ultimate resilience: IP55 protection plus 5000-hour salt spray testing, 15-year lifespan, and 80% lower maintenance costs.

- Ultimate intelligence: AI-powered O&M platform enables 90% of faults to be remotely diagnosed and resolved, minimizing on-site visits.

V2G: Pioneering the future of vehicle-to-grid interaction

EAST Group has also forward-lookingly introduced 30/60/120kW V2G all-in-one units, supporting millisecond-speed charge-discharge switching to help grids balance peak and valley loads. Stations with 35kW+ piles can see annual revenue growth of 120,000 yuan, while users earn subsidies for each discharge session.

O&M Upgrade: End-to-End Assurance Framework

On quality, EAST Group is a 3C certification pioneer, among the first to secure certification for 120kW DC chargers. Every unit undergoes 72-hour aging tests and extreme environment trials before shipment, ensuring compliance and reliability.

On O&M, EAST Group offers a “dual-platform + mini-program” package: The dual platforms deliver 100% automatic fault detection and 90% remote resolution; the “Yidianzhuang” mini-program supports one-click pile search and scan charging, with Baidu and Gaode Maps integration boosting exposure by 30%.

For operators, EAST Group provides T+1 withdrawals and precision pricing. Projects with clients like Zijin Mining and Sinopec have achieved “zero on-site maintenance,” cutting operational costs substantially.

The conference served as a vital platform for exchanges aimed at advancing quality enhancement and innovative growth of charging infrastructure. In the future, Eastone anticipates joining hands with more excellent partners to tighten quality improvement efforts and sharpen technological innovation, collectively powering the new era of zero-carbon new energy.